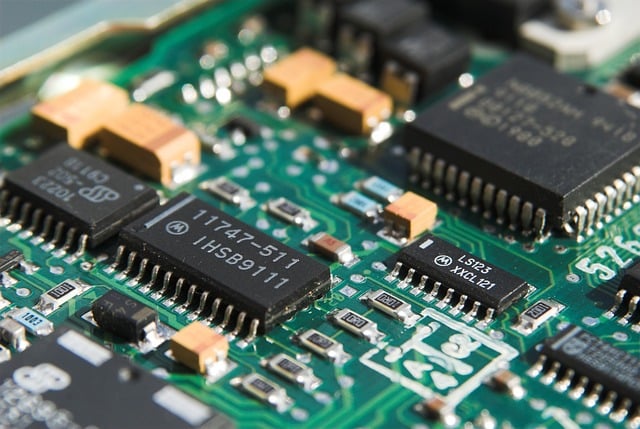

Printed circuit boards (PCBs) are the unsung heroes of modern electronics. These thin, layered boards are the foundation for countless devices, from smartphones and laptops to medical equipment and satellites.

It is predicted that the global PCB market is anticipated to reach a staggering USD 85.42 billion by 2028, driven by factors like miniaturization and the ever-growing demand for complex electronics.

However, the quality of PCBs directly influences the performance and reliability of these devices.

Even minor imperfections in materials or manufacturing can lead to malfunctions, shortened lifespans, or even safety hazards. This is where material selection and supply chain management become crucial.

PCB manufacturers can ensure consistent product performance and reliability by carefully selecting high-quality materials and implementing robust supply chain practices. This translates into numerous benefits for potential customers, including:

- Enhanced device functionality

- Increased reliability

- Reduced manufacturing costs

In the following blog post, you will delve deeper into the importance of material selection for PCBs, explore the intricacies of supply chain management, and explain how these practices contribute to creating high-quality PCBs.

So, let’s take a look at it.

Understanding PCB Materials

As you know, PCBs, or printed circuit boards, are the thin, layered boards that form the foundation of countless electronic devices. They act like tiny highways, containing copper traces that carry electrical signals and connect various electronic components.

These are made of different materials used for the base layer (substrate), the conductive pathways (copper foil), and the insulating layer (dielectric) based on factors like cost, performance, and application. The foundation of any high-quality PCB lies in its materials.

PCB fabricators utilize various materials, each with distinct electrical and mechanical properties.

Common choices include FR-4, a cost-effective and fire-retardant material ideal for everyday electronics. For high-frequency applications, materials like Polyimide offer superior signal integrity. CEM-based PCBs balance cost and performance, while rigid-flex PCBs combine rigid and flexible sections for unique design possibilities.

Selecting the suitable material depends heavily on the application. Environmental factors like temperature range and moisture exposure are crucial considerations. Cost plays a significant role, with FR-4 generally being the most affordable option. Ultimately, consistent material quality is paramount. Reliable suppliers and robust quality control ensure PCBs meet their intended purpose and deliver long-lasting performance.

Let’s learn about them in detail.

Material Selection for High-Quality PCB

First, selecting the right materials is the cornerstone of creating high-quality PCBs. This section explores the key components and their properties:

Substrate (Base Material)

- FR-4 (Flame Retardant 4): The undisputed champion, FR-4 is the most widely used PCB substrate due to its affordability, good electrical performance, and flame resistance. It’s a laminate composed of woven glass fibers embedded in epoxy resin. FR-4 offers decent thermal properties and dimensional stability, making it suitable for various applications in consumer electronics, computers, and industrial controls.

- Properties: Affordable, good electrical performance, flame retardant, decent thermal properties, dimensionally stable.

- Features: Most widely used PCB substrate, laminate of woven glass fibers, and epoxy resin.

- Price: Relatively inexpensive.

- Application Fields: Consumer electronics, computers, industrial controls, and various general-purpose applications.

Alternatives: For specific needs, alternatives exist

- FR-1: A more economical option with lower heat resistance than FR-4, suitable for low-power applications.

- Properties: Lower cost, lower heat resistance than FR-4.

- Features: More economical option for low-power applications.

- Price: Very affordable.

- Application Fields: Low-power devices, calculators, radios, and simple circuits.

- Metal-Clad Invar: This material boasts exceptional dimensional stability with minimal thermal expansion, making it ideal for high-precision applications like aerospace and medical devices. However, its higher cost limits its widespread use.

- Properties: Exceptional dimensional stability, minimal thermal expansion.

- Features: Ideal for high-precision applications due to minimal size variation with temperature changes.

- Price: Expensive.

- Application Fields: Aerospace and defense equipment, medical devices, and high-precision instruments.

- Polyimide: When electrical performance at high frequencies is critical, Polyimide shines. Its low dielectric constant minimizes signal loss, making it the preferred choice for high-speed circuits and RF applications. However, Polyimide requires specific fabrication techniques due to its high melting point and can be more expensive than FR-4.

- Properties: Excellent electrical performance at high frequencies, low dielectric constant, good chemical resistance.

- Features: Minimizes signal loss at high speeds, suitable for RF applications. Requires specific fabrication techniques due to high melting point.

- Price: More expensive than FR-4.

- Application Fields: High-speed circuits, RF applications, telecommunication equipment, microwave components.

- Rigid-Flex PCBs: These innovative PCBs combine rigid FR-4 and flexible polyimide sections. This allows for unique three-dimensional designs impossible with rigid PCBs alone, often used in applications with space constraints or requiring dynamic movement. Material selection for rigid-flex PCB is crucial, as FR-4 and polyimide properties must be considered for optimal performance and flexibility.

- Properties: Combines rigid and flexible sections, offering unique design possibilities.

- Features: Allows for 3D designs, suitable for space-constrained applications or those requiring movement. Requires careful material selection for optimal performance and flexibility.

- Price: Generally more expensive than standard rigid PCBs due to complex fabrication.

- Application Fields: Portable electronics, mobile devices, automotive applications, and medical devices requiring flexibility.

Copper Foil

The conductive layer carries electrical signals, and copper foil has various thicknesses. The weight (oz/ft²) determines the current carrying capacity. Thicker copper allows for higher currents but increases fabrication complexity and cost. Conversely, thinner copper reduces cost but limits current capacity. Selecting the appropriate copper weight is crucial for ensuring proper signal strength and heat dissipation based on the application’s current requirements.

Dielectric Layer

This insulating layer separates the copper traces and plays a vital role in signal integrity. The material’s dielectric constant (Dk) determines the signal propagation speed on the PCB. Lower Dk values translate to signal transmission, which is crucial for high-frequency applications. FR-4 has a moderate Dk, while materials like Polyimide offer exceptionally low Dk values, making them ideal for high-speed circuits. Choosing the right dielectric material ensures signals travel efficiently, minimizing signal loss and maintaining circuit functionality.

Factors to Consider When Selecting PCB Materials

Choosing the ideal PCB material goes beyond just basic functionality. It’s about striking the perfect balance between various factors to ensure optimal performance and reliability in your final product. Here are the key considerations:

Electrical Requirements

- Conductivity: This refers to the material’s ability to conduct electricity. Copper, being the primary conductor in PCBs, boasts excellent conductivity. However, alternative materials like high-conductivity metals might be considered for specific applications.

- Dielectric Constant (Dk): As discussed earlier, Dk significantly impacts signal integrity. Lower Dk values minimize signal loss and ensure faster signal transmission. High-frequency applications like RF circuits typically require materials with exceptionally low Dk, such as Polyimide.

- Dissipation Factor (Df): This value represents the energy lost as heat within the dielectric material during signal transmission. A lower Df indicates less energy loss and better signal quality. Dk and Df are crucial in maintaining signal integrity, particularly for high-speed circuits.

Mechanical Requirements

- Flexural Strength: This refers to the material’s ability to resist bending before breaking. It’s crucial for applications with potential physical stress or requiring a rigid structure. FR-4 offers good flexural strength, while rigid-flex PCBs utilize materials like polyimide for flexibility in specific sections.

- Coefficient of Thermal Expansion (CTE): Different materials expand and contract at varying rates with temperature changes. A well-matched CTE between the PCB material and the components mounted on it minimizes stress and potential cracking of solder joints during thermal cycling. This is particularly important for applications experiencing significant temperature fluctuations.

- Dimensional Stability: Maintaining consistent dimensions throughout the PCB’s lifespan is crucial. Materials like FR-4 and metal-clad Invar offer good dimensional stability, ensuring the PCB retains its precise shape and component placement.

Environmental Considerations

- Temperature Range: The PCB must function reliably within the expected operating temperature range. FR-4 performs well in moderate temperatures, while high-temperature applications might require alternative materials like polyimide, which can withstand higher temperatures.

- Fire Resistance: Some applications prioritize flame-retardant properties. FR-4, as the name suggests, offers good fire resistance for various electronics.

- Moisture Absorption: Moisture absorption can impact electrical properties and potentially lead to malfunctions. Materials with low moisture absorption, like polyimide, might be preferred for environments with high humidity.

Cost

Material selection significantly impacts the overall PCB cost. FR-4 remains the most cost-effective option, while high-performance materials like Polyimide or metal-clad Invar come at a premium. Finding the right balance between material cost and the desired performance level for your specific application is vital.

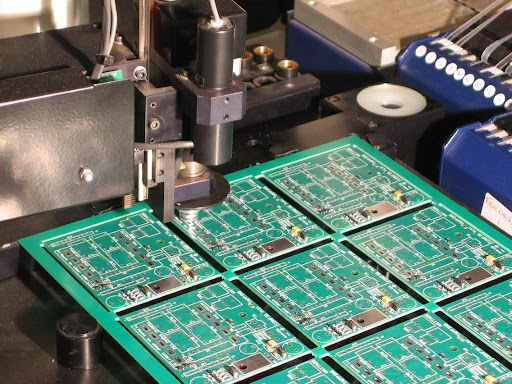

Importance of Supply Chain Management in PCB Manufacturing

A robust supply chain forms the backbone of high-quality PCB manufacturing. The intricate network ensures the right materials arrive at the right time in the proper condition. Here’s how a well-managed supply chain contributes to success:

Benefits of a Robust Supply Chain

-

Consistent Material Quality

Reliable PCB manufacturers prioritize partnering with established, reputable suppliers who adhere to strict quality control standards. This ensures consistent material properties across batches.

For example, consistent Dk values in the dielectric material translate to predictable signal integrity on the final PCB. Similarly, consistent copper foil thickness guarantees reliable current carrying capacity. Reliable suppliers minimize the risk of material inconsistencies that could lead to performance issues or production delays.

-

On-Time Delivery

Effective supply chain management involves meticulous planning and lead time management. This ensures a steady flow of materials to meet production schedules. Delays in receiving critical components can disrupt production lines and lead to missed deadlines.

A well-managed supply chain proactively identifies potential bottlenecks and implements strategies to mitigate them. This keeps production running smoothly and ensures timely delivery of finished PCBs to your customers.

-

Cost Optimization

Negotiating competitive material prices with reliable suppliers directly impacts production costs. Strong supplier relationships and strategic sourcing practices help manufacturers secure the best material deals.

Additionally, a well-managed supply chain minimizes waste and reduces the need for emergency material purchases at inflated prices. This translates to cost savings that can be passed on to the customer.

Printed circuit board manufacturers can overcome the challenges by prioritizing a well-managed supply chain and ensuring consistent quality, timely deliveries, and cost-effective production. This translates into high-quality PCBs that meet your needs and deliver optimal performance.

Trust PCBLOOP For High-Quality PCBs!

At PCBLOOP, we leverage over 20 years of experience to deliver high-quality PCBs that meet your needs. We prioritize robust quality management systems certified to ISO 9001:2015 and other industry standards. Our meticulous pre-production review process catches potential Gerber file errors, saving you time and money by preventing costly re-spins.

Our commitment to a reliable supply chain ensures consistent material quality for predictable performance. By combining these factors with stringent testing procedures and a dedication to on-time delivery, PCBLOOP guarantees exceptional PCBs that empower your high-tech products.